How to test the life of LED chips

As an electronic component, Light Emitting Diode-led (Light Emitting Diode-led) has been around for more than 40 years, but for a long time, it has been limited by luminous efficiency and brightness and only used for indicator lights. Until the end of the last century, it broke through the technical bottleneck and produced high brightness and high efficiency. The LEDs and blue light LEDs extend the application range to signal lights, urban night scene projects, full-color screens, etc., providing the possibility of being used as a lighting source. As the scope of LED applications increases, improving the reliability of LEDs is of even greater significance.

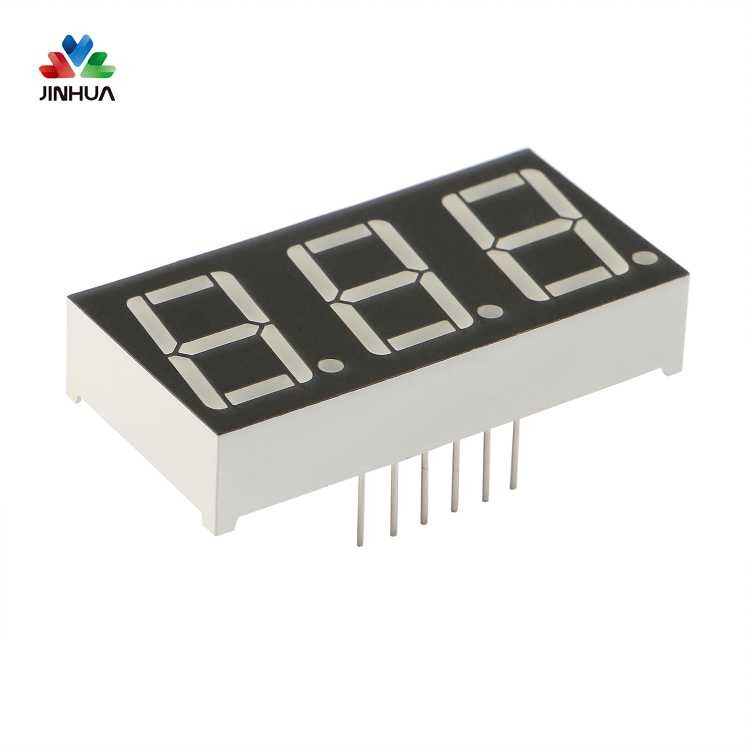

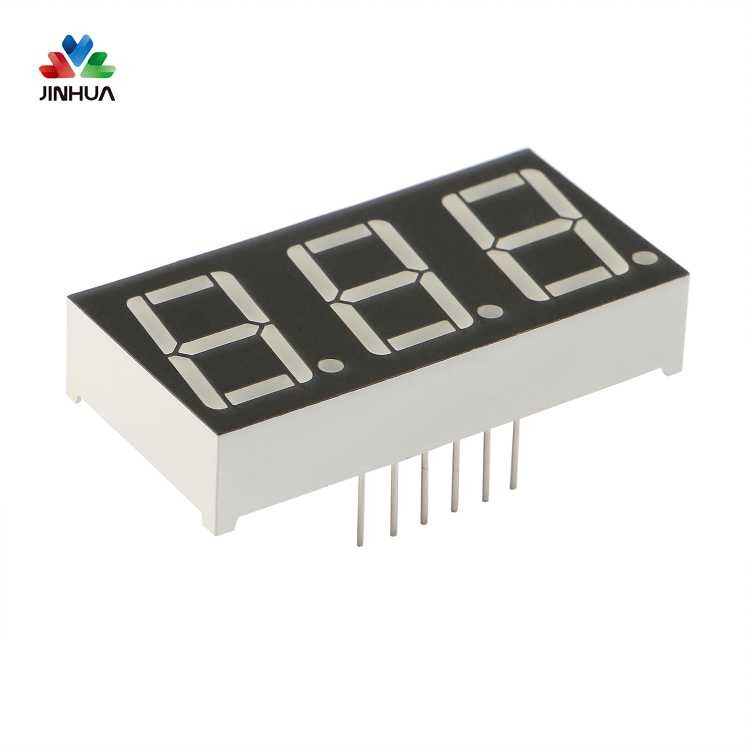

LED has the advantages of high reliability and long life. In the actual production and development process, the reliability level of the LED chip needs to be evaluated through the life test, and the reliability level of the LED chip is improved through quality feedback to ensure the quality of the LED chip For this reason, while realizing the industrialization of full-color 7 segment LED display, the conditions, methods, means and devices of the LED chip life test have been developed to improve the scientificity of the life test and the accuracy of the results.

Determination of life test conditions

The working test of electronic products under specified working and environmental conditions is called life test, also called durability test.

With the improvement of LED production technology, the life and reliability of products have been greatly improved. The theoretical life of LED is 100,000 hours. If the conventional life test under normal rated stress is still used, it is difficult to determine the life and reliability of the product. Make a more objective evaluation, and the main purpose of our experiment is to grasp the light output attenuation of the LED chip through the life test, and then infer its life.

According to the characteristics of LED display module devices, after comparative experiments and statistical analysis, the life test conditions of chips below 0.3×~0.3mm2 are finally specified:

Samples are randomly selected, the number is 8-10 chips, made into ф5 single lamp;

Working current is 30mA;

The environmental condition is room temperature (25℃±5℃);

The test period is 96 hours, 1000 hours and 5000 hours.

The working current of 30mA is 1.5 times of the rated value. It is a life test with increased electrical stress. Although the result cannot represent the real life, it has great reference value; the production batch of the extension wafer in the life test is the mother sample, random Take 8 to 10 chips from one of the epitaxial wafers, package them into a ф5 single lamp device, and conduct a 96-hour life test. The results represent all epitaxial wafers in this production batch.

It is generally believed that a test cycle of 1000 hours or more is called a long-term life test. When the production process is stable, the 1000-hour life test frequency is lower, and the 5000-hour life test frequency can be lower.

Process and precautions

For LED chip life test samples, chips, generally called bare crystals, can be used, or packaged devices can also be used. Using bare crystal form, the external stress is small, easy to dissipate, so the light attenuation is small, the life is long, and the actual application situation is large, although it can be adjusted by increasing the current, it is not as intuitive as directly using the single-lamp device.

English

English Deutsch

Deutsch русский

русский español

español العربية

العربية

IPv6 network supported

IPv6 network supported