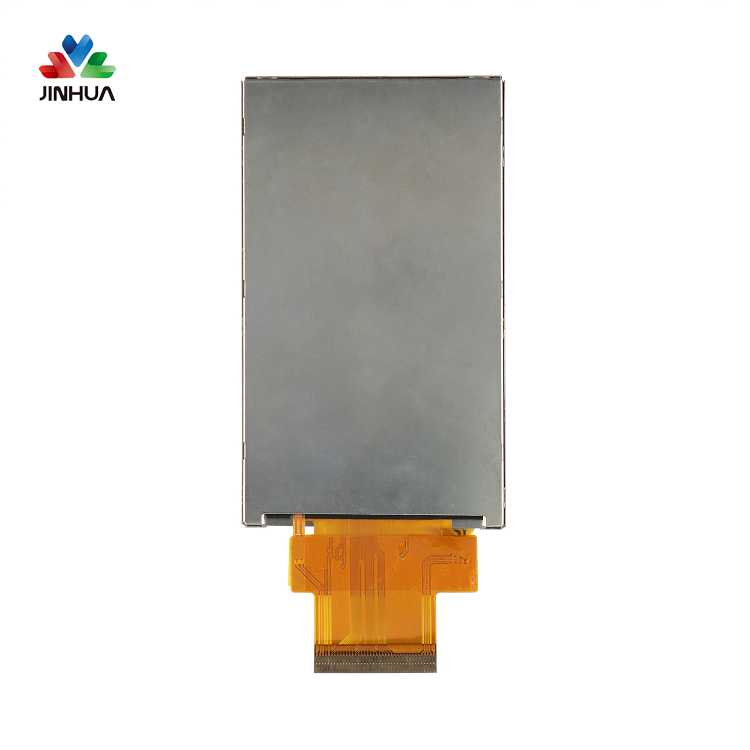

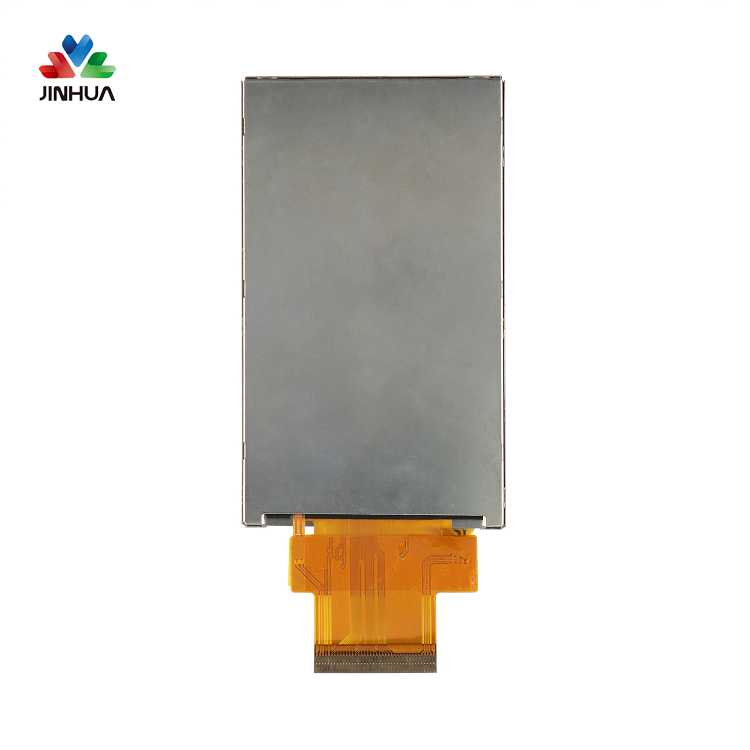

2. Assembly process (cell)

1) After finishing the thin film transistor glass substrate, we will proceed to the combination of the liquid crystal module. The liquid crystal panel is composed of the transistor glass substrate and the color filter. First, we must clean the glass first, and then proceed One step. The entire manufacturing process of TFT-LCD must be in a clean room, so that there will be no impurities in the display.

2) The color filter is a chemical coating method to form red, green, and blue colors on the glass. After neatly arranged, it is completed by covering a layer of conductive film.

3) During the entire assembly process, first we have to apply a chemical film to the glass and color filters covered with transistors, and then perform the alignment action.

4) Before combining the two glass plates, we must first evenly cover the spherical-shaped gaps at a fixed interval to prevent the two glass plates from bending inward after the liquid crystal panel is combined. Usually, when the liquid crystal panel is assembled, one or two gaps are left to facilitate the subsequent filling of the liquid crystal, and then the edge of the two pieces of glass is sealed with sealant and conductive glue, thus completing the glass assembly.

5) After sealing the frame, place the LCD panel in the vacuum chamber, and drain the air from the LCD module through the gap just reserved, and then pour the liquid crystal with the help of atmospheric pressure, and then close the gap. The liquid crystal is a kind of The compound substance between solid and liquid has the characteristic of regular molecular arrangement.

6) Finally, attach two vertical polarizers, and the entire LCD panel is completed.

Tft manufacturing principle and simple manufacturing process

3. Module manufacturing process (module)

1) After the polarizer is attached, we start to mount DRIVE IC on both sides of the LCD panel. DRIVE IC is a very important driving part, which is used to control the color and brightness of the liquid crystal.

2) Then connect the input end of the DRIVE IC to the circuit board by soldering. In this way, the signal can be sent out smoothly, and then the image on the control panel is ready.

3) The light of the LCD panel is emitted from the backlight. Before assembling the backlight, we will first check whether the assembled LCD panel is perfect, and then assemble the backlight. The backlight is the source of light behind the LCD panel.

4) Finally, lock the CELL and the iron frame with screws.

5) After that, we entered the final critical test process. The assembled modules are subjected to aging test, and products with poor quality are screened out in the power-on and high-temperature state.

6) The best quality products can be packaged and shipped.

English

English Deutsch

Deutsch русский

русский español

español العربية

العربية

IPv6 network supported

IPv6 network supported